Taiwan Semiconductor Manufacturing Company

TSMC Delays Start of First Arizona Chip Factory, Citing Worker Shortage

Semiconductor maker forecasts sales drop this year but predicts boom in AI-related business

July 20, 2023

TSMC Postpones Mass Production at Arizona Fab to 2025 | Tom's Hardware

TSMC Postpones Mass Production at Arizona Fab to 2025

TSMC on Thursday stated that it would have to delay the start of large-scale production at its Fab 21 in Arizona to 2025. The setback comes as a result of an inability to set up all the necessary cleanroom tools in a timely manner, largely due to a shortage of qualified staff. To rectify this, TSMC is deploying approximately 500 of its Taiwanese personnel with hands-on experience in fab tools installation.

"While we are working on to improve the situation, including sending experienced technicians from Taiwan to train local skill workers for a short period of time, we expect the production schedule of N4 process technology to be pushed out to 2025," said Mark Liu, chairman of TSMC, during the company's earnings call with financial analysts and investors. "We are encountering certain challenges, as there is an insufficient amount of skilled workers with the specialized expertise required for equipment installation in a semiconductor-grade facility."

The hurdles that TSMC encountered are serious enough for the foundry to push back the start of mass production at Fab 21 phase 1 from early 2024 to sometimes in 2025, representing a delay of approximately a year. The company has not yet specified an exact timeline for when in 2025 it plans to begin mass producing chips in Arizona.

It remains to be seen how the delay of TSMC's Fab 21 launch will affect its customers in the U.S. On the one hand, the company can just 're-route' orders from clients like Apple, AMD, and Nvidia to its Taiwan fabs. But on the other hand, its fabs in Taiwan may be running at full capacity in 2024. Furthermore, clients like AMD and Nvidia may want to produce certain items for the U.S. government in the USA and delaying them by a year could be a breach of contract.

Construction of TSMC's Fab 21 phase 1 commenced in April 2021 and concluded around mid-2022, slightly later than originally planned. In December, 2022, TSMC started to install its equipment. Based on standard procedure, a cleanroom setup within a fab typically takes about a year, which is why TSMC originally forecasted that the fab would go online in early 2024.

However, the local workforce's unfamiliarity with TSMC's specific needs has led to various delays in setting up production tools at Fab 21.

Just last month, TSMC confirmed ongoing negotiations with the U.S. government aiming to secure non-immigrant visas for its Taiwanese specialists to work in the U.S. Based on a Nikkei report, TSMC was going to dispatch some 500 technicians who can set up fab tools as well as mechanical and electrical systems for fabs.

Taiwan Semi’s First Profit Fall in Four Years—AI Isn’t Boosting All Chip Stocks Yet

Taiwan Semiconductor has poured cold water on hopes of a chip recovery again. The world’s largest contract chip maker is still grappling with a slump in demand for electronic devices, which is a poor sign for rivals such as Intel INTC –0.12%

________________________________________________________________________________

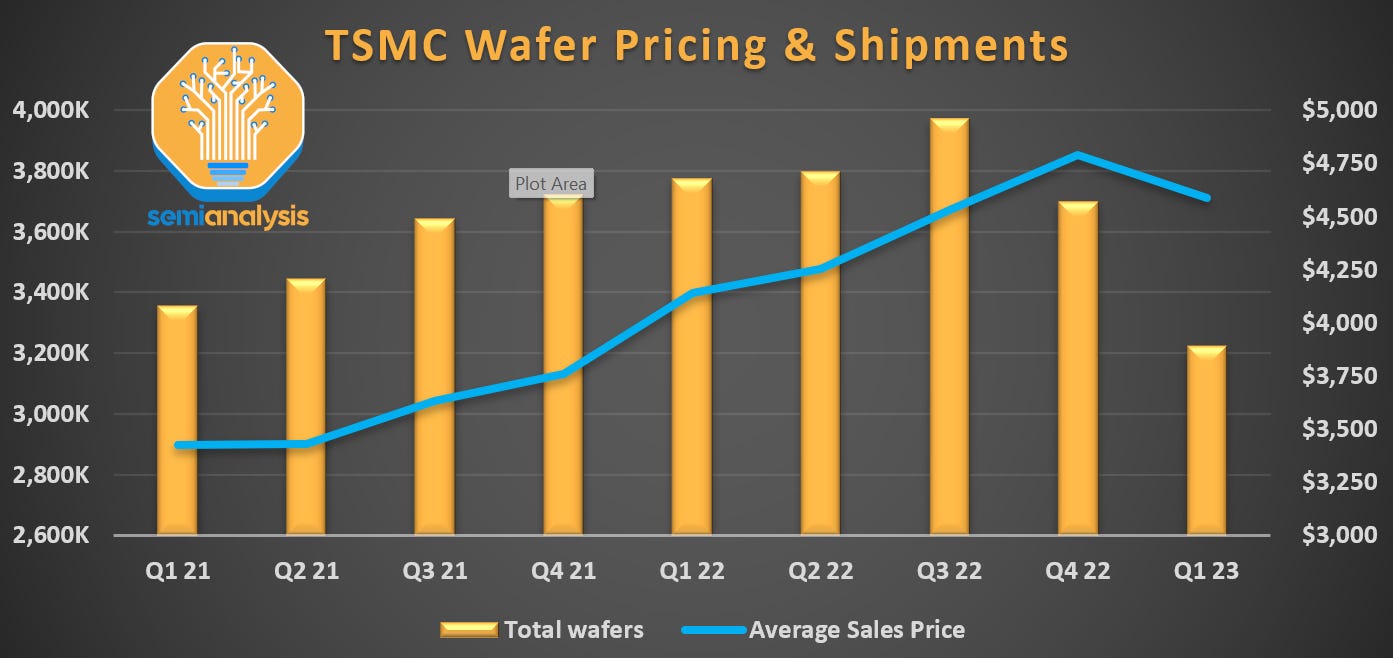

- TSMC reported revenue slipped 10% from a year ago to NT$480.84 billion, while net income fell 23.3% from a year ago to NT$181.8 billion.

- The second quarter revenue and net income figures were better than market expectations.

- TSMC is the top producer of the world’s most advanced processors, but demand for consumer electronics has plunged post-pandemic.

Twitter Results

>

_

No comments:

Post a Comment